Creating the Cutting Edge

By Presley Price

From rockets that launch from below the sea, to ground, air and space-launched rockets, our customers rely on Northrop Grumman propulsion systems to conduct their most important missions.

Northrop Grumman has more than 70 years of experience providing high-performance and reliable propulsion systems to the aerospace and defense industries. Our solid rockets helped explore the boundaries of space in the 1950’s and land on the moon for the first time in 1969, while also pioneering the design and testing of hypersonic engines.

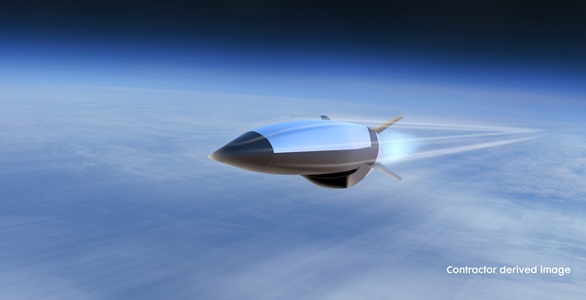

Today, Northrop Grumman continues to solve the industry’s most challenging problems with innovative solid and airbreathing solutions. In 2022, Raytheon Missiles & Defense, a Raytheon Technologies business, in partnership with Northrop Grumman were selected to develop the USAF’s Hypersonic Attack Cruise Missile (HACM) – a first-of-its-kind airbreathing hypersonic weapon. Northrop Grumman will produce the propulsion system enabling the missile at the Hypersonics Capability Center located on the Elkton, Maryland campus.

The facility is the first in the U.S. designed for large-scale manufacturing of air-breathing propulsion critical for powering hypersonic missiles beyond Mach 5 and will make affordable, high-rate production of hypersonic weapons a reality.

Hypersonics Capability Center

A Rich Heritage

The Hypersonics Capability Center is one of more than 150 other buildings across the 550-acre campus providing support to dozens of programs delivering a diverse range of propulsion systems for civil, national security and commercial rockets.

The facility holds a rich heritage of solid-propellant rocket manufacturing dating back to 1948 when the site was established. Since then, the facility has supported orbit insertion of commercial and GPS satellites, used controllable solid propulsion to intercept ballistic missile targets, and demonstrated that a scramjet could fly 10 times faster than the speed of sound. Today, it’s the premier advanced propulsion manufacturing facility offering tip to tail capabilities in one campus.

At the Forefront

Northrop Grumman is at the forefront of hypersonic technology and truly leading the industry with its expertise, products and continual investment to grow its capabilities. The company has invested across the Elkton campus to modernize equipment used to produce well established product lines, digitize new processes and product design, and integrate scalable additive manufacturing. The campus incorporates leading-edge digital manufacturing methodologies, including the use of smart equipment, paperless work instructions and processing, and modular automated work cells. The result is more efficient manufacturing practices, shorter lead time for products and lower costs for customers. Each facility upgrade is made with capacity expansion in mind, meaning these investments will support a robust, reliable supply chain to meet the DoD’s demands today and for the future.

“We are truly creating the cutting edge in the defense industry,” said Sean Peiffer, energetics manufacturing engineer. “I’ve never worked at a facility that has invested so significantly in this technology.”

A Culture Dedicated to Shared Success

According to Brian Tester, manufacturing engineer, it’s not just the cutting-edge technology that sets the Elkton campus apart – it’s also the culture. While Northrop Grumman has grown to 95,000 employees, the Elkton, Maryland team has maintained a close, family-like culture committed to a shared mission of success.

With just over 700 employees at Elkton, the team is agile and adaptive, providing support for dozens of programs.

"Each day we are Defining Possible by overcoming our customers' most complex problems. Working together towards a common goal of providing our military with an overmatch needed to protect global security gives us all a sense of pride in what we do," said Brian.

Key Investments to Ensure Mission Readiness

Allegany Ballistics

Laboratory, WV

• 2022 Missile Integration Facility

• Significant Facility Improvements