The first time Jasmine saw a 3D-printed airplane part, she felt like she was starting an adventure.

“I was making fuel doors and they were kind of this odd, oblong shape, and they 3D printed a bunch of prototypes for a check fit,” she recalled. “They arrived in these huge, wooden crates like something out of ‘Indiana Jones and the Raiders of the Lost Ark.’ They looked so cool.”

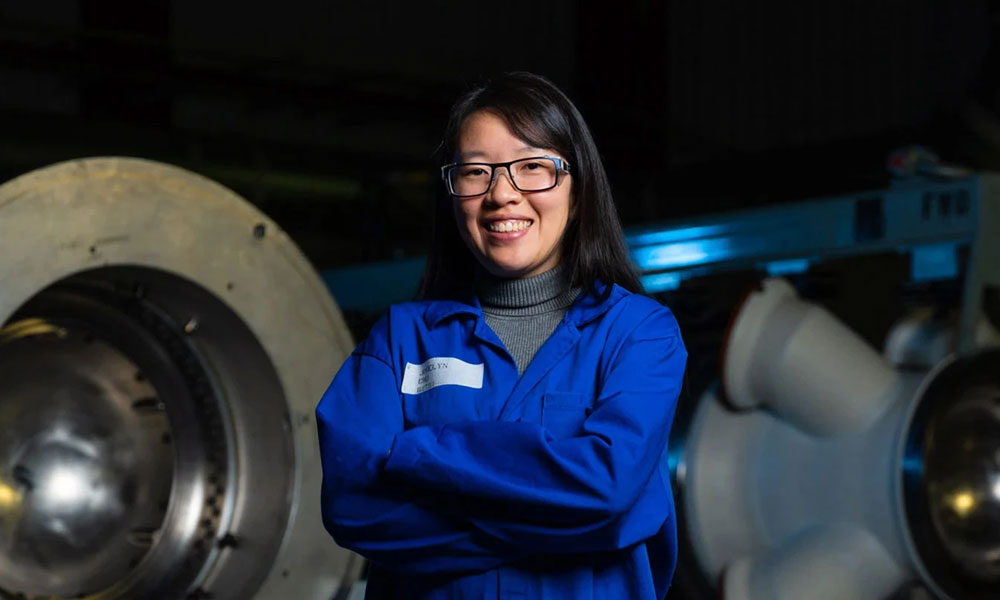

Since then, 3D printing – also known as additive manufacturing – has lead Jasmine down an exciting career path. She has become a product champion for Northrop Grumman’s additive manufacturing group, where she studies additive materials and advocates their use. The role is unique at Northrop Grumman, she said, particularly because she was encouraged to pursue it and learn on the job.

“I’d never used a 3D printer, but I told my team lead that I was really interested in this, and he said, ‘OK, run with it,’” she said. “No one stood in my way. I was able to let my imagination go.”

“I really love the fact that Northrop Grumman just lets you take your career where you want to go.”

Jasmine, Manufacturing Design Engineer

Jasmine joined the additive manufacturing team several years ago after attending a lunch and learn about additive manufacturing. She approached the group to learn more and was pleasantly surprised that, even though she didn’t have a background in the field, they encouraged her to study it and become an ambassador for the technology. She found other employees on her program who were interested as well, and they worked together to find out who they needed to meet and what they needed to learn in order to put additive manufacturing into wider use.

“I just kind of brute forced it,” she said with a laugh. “We teamed up and joined forces to make this thing actually happen.”

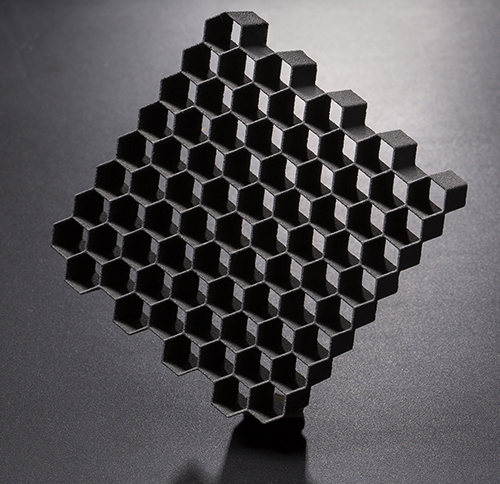

A manufacturing design engineer by training, Jasmine works on the U.S. Air Force B-2 Spirit program in Oklahoma City. She advocates for a material called electrostatic dissipative PolyEtherEtherKetone with discontinuous fibers, better known as ESD PEKK, or just PEKK. A plastic polymer mixed with carbon fibers, PEKK is lightweight, and like all 3D-printed materials, it can be made into very specific shapes without the time-consuming process of using tooling. The material has electrostatic dissipative properties that are valuable aboard air and space vehicles because it can absorb static electricity and discharge it without causing damage. It can also withstand high levels of heat and radiation. Through Jasmine’s work, several programs have begun using PEKK to make parts.

“I want Northrop Grumman to use additive manufacturing more and more for flight-ready production parts, and not just prototyping,” she said. “I think we should start manufacturing bigger and bigger pieces with additive manufacturing.

Jasmine decided she wanted to be an aerospace engineer in seventh grade, after she won an essay contest to attend space camp. The idea that she is now working on futuristic materials that fly on airplanes and spacecraft adds a layer of excitement to her job.

“I really love the fact that Northrop Grumman just lets you take your career where you want to go,” she said.

Life at Northrop Grumman: Recent Stories

Shape your career journey with diverse roles and experiences that expand your expertise, feed your curiosity, and fuel your passion.

Life at Northrop Grumman: Archived Stories

It takes every one of us to make the impossible a reality. See what life is like at Northrop Grumman.