Propulsion Technologies

Northrop Grumman has been advancing propulsion technology since 1958.

Our earliest work involved cold gas, heated gas, and liquid bipropellant and monopropellant rockets and boosters; we continue to further these technologies. For example, Northrop Grumman was selected by NASA to be one of the developers of new propulsion technology for potential use on next-generation launch and space transportation vehicles.

We have been developing electric propulsion since the 1970s and have made recent world-class advances in gel propellant propulsion.

Our fundamental research and development has been applied to a range of flight hardware for a wide range of space missions. Recent flight successes of propulsion systems have included NASA's Chandra X-ray Observatory, the Army's gel-powered FMTI missile, and a SCAT-powered spacecraft.

Booster Vehicle Engines

Northrop Grumman is developing booster vehicle engines that will provide low-cost access to space.

Based on Northrop Grumman's pintle engine technology, Northrop Grumman's 650,000-pound thrust TR-106 engine is one of the largest liquid rockets ever built. It has been successfully test fired at 100 percent of its rated thrust as well as at 65 percent throttle condition in tests at NASA's John C. Stennis Space Center.

Designed as a simple, easy-to-manufacture, low cost engine, the TR-106 has parts made from common steel alloys using standard industrial fabrication techniques, uses ablative cooling techniques in place of more expensive regenerative cooling, and features the least complex type of rocket propellant injector a single element coaxial pintle injector. The pintle injector contains only five parts (excluding seals, attachment nuts, bolts and washers).

Electric Propulsion

Northrop Grumman has been developing selected electric propulsion technologies and systems since the 1970s. A Northrop Grumman-developed arcjet system, launched in 1999, is the highest power (30kW) electric propulsion system flown to date. The company is now developing a 200 W Hall propulsion system to support a demonstration of formation-flying three satellites.

Electric propulsion can be used for multiple types of in-space missions, from inserting spacecraft into specific orbits to repositioning spacecraft, stationkeeping, and constellation management. Electric thrusters have much higher specific impulse than chemical thrusters, and provide two to three times more fuel efficiency. Higher fuel efficiency means less propellant is needed on-board, allowing spacecraft designers to reduce overall spacecraft weight and launch costs or to add more weight and capability to the payload.

Gel and Tactical Propulsion

Fly smart with gel propulsion.

Combining the best features of solid- and liquid-fueled rocket engines, Northrop Grumman's versatile gel propellant system provides the on-demand thrust needed for smart flight. Its energy management capabilities improve targeting, allow rapid maneuverability and extend missile range. This flexibility allows one missile system to perform multiple missions, reducing overall operation and support costs. Northrop Grumman's gelled propulsion system was developed and successfully flight-tested on the U.S. Army's Aviation and Missile Command (AMCOM) Future Missile Technology Integration (FMTI) Program.

Northrop Grumman's patented face-shutoff engine enables gel propulsion system operation. Gel propellants exhibit the consistency of thick mayonnaise, but will liquefy and combust when pressurized. These semi-solid propellants do not leak, detonate or explode under adverse conditions. Gel propellants are safe and environmentally sound and can be disposed of at 1/10th the cost of solid propellants.

Monopropellant

Northrop Grumman has developed, qualified and flown spacecraft monopropellant thrusters for on-orbit delta velocity and attitude control for a variety of spacecraft for more than 25 years. Our family of catalytic monopropellant hydrazine thrusters range in size from 0.1 lbf thrust to 15 lbf thrust. These thrusters all share the unique Northrop Grumman head space design, utilize Shell 405 catalyst, and incorporate bed loadings consistent with long life. For robustness and maximum user flexibility, all thrusters are qualified with monopropellant grade hydrazine. We recently requalified our 0.2 lbf thruster for the long-life Chandra X-ray Observatory mission.

Related News

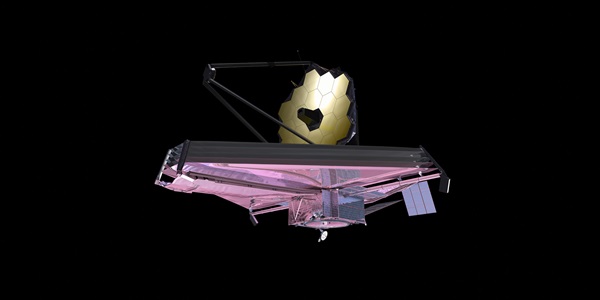

Fabrication of Northrop Grumman-Built Spacecraft for NASA's James Webb Space Telescope Moves Forward With Design Completion of Key Communications Structure

Northrop Grumman-Built STSS Demonstration Satellites Participate in Test of Next-Generation Aegis Ballistic Missile Defense Weapon System