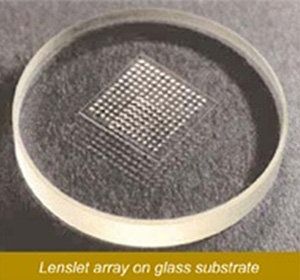

Monolithic Lenslet Modules

Monolithic Lenslet Modules (MLMs), are arrays of refractive micro lenses.

Monolithic Lenslet Modules (MLMs), are arrays of refractive micro lenses.

Monolithic Lenslet Modules (MLMs), are arrays of refractive micro lenses. Many arrays can be replicated from a single MLM master. The master is fabricated by a proprietary, computer controlled mastering process developed by AOA Xinetics. The arrays can be made with full edge to edge lenslet contact to maximize fill factor and optimize transmission efficiency. Parts have been made using epoxy-on-glass replications and solid hot-pressed and injection-molded acrylic, polystyrene and polycarbonate plastics, chemical-vapor-deposited (CVD) zinc selenide, solgel fused silica and many other materials. Applications include: diode laser collimation and focusing, video display enhancement, panoramic imaging, multiple beam scanning, and plenoptic imaging.

AOA Xinetics proprietary design process allows custom array designs as large as 20 cm x 20 cm. The lenslet pitch can be as small as 15 microns or as large as 4 millimeters. Other array sizes and lenslet sizes may be developed on a custom basis.

AOA Xinetics catalog of standard lenslet arrays are made of epoxy replicated onto one of four BK 7 windows. All windows offered are made from Grade A BK7, polished to a surface flatness of λ/4 (at 632.8 nm) over the clear aperture.

A broadband anti-reflection (AR) coating is provided on the glass side of each epoxy-replicated substrate. The AR coating is optimized for the 400 –700 nm wavelength region, providing < 0.5% reflection loss. Coatings for other wavelengths are also available.