Hypersonics

Ushering in a new era for faster, more survivable, highly capable weapons.

Scramjet Hypersonic Propulsion

Scramjet technology ushers in a new era for faster, more survivable, highly capable weapons. Not only does scramjet propulsion advance speeds greater than Mach 5 and maneuverability never seen before in traditional missiles, but it also leads to a smaller form factor missile while offering more capability. This means platforms can carry more weapons in less space.

Hypersonic Strike

Flying faster than a mile a second, facing scorching 2,000°F temperatures, all while maneuvering throughout flight, hypersonic missiles test the limits of possible.

We’re at the forefront of innovation, tackling seemingly impossible challenges to help create new classes of strategically important propulsion systems for our nation. With industry leading ramjets, scramjets and boosters, advanced materials, and full life-cycle development, we are leading the way for faster, more survivable, highly capable hypersonic weapons.

Facilities and Investments

To usher in a new era of military readiness, Northrop Grumman opened its Hypersonics Capability Center in Elkton, MD. Holistically designed to provide full lifecycle production, from design and development to production and integration for hypersonic propulsion systems, Northrop Grumman is defining possible to meet the Hypersonic Challenge.

Hypersonic Boost Glide Propulsion

Hypersonic boost glide propulsion vehicles briefly exit and reenter the atmosphere, then glide and maneuver at hypersonic speeds to their targets – a combination that makes them extremely difficult to track and very effective as fast-attack weapons.

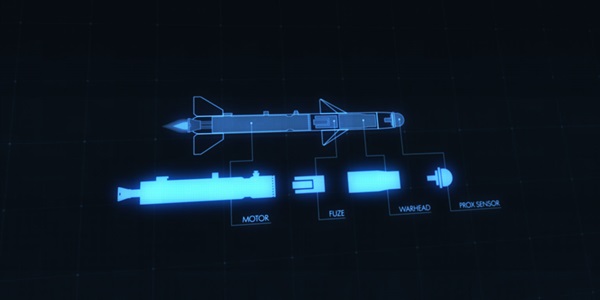

Fuzes and Warheads

Building on our expertise as the only company to integrate both fuzes and warheads, Northrop Grumman’s warhead system is efficiently designed in a smaller package to support extended range and speed of the propulsion system.

Counter Hypersonics

Protecting the homeland and our regional forces against hypersonic capabilities from peer adversaries through detection, tracking and defensive technologies.

Our Edge

Testing

The Aerothermal Research and Testing facility tests the capabilities of electronics and equipment at conditions simulating speeds up to Mach 8.

Disruptive Technologies

Advanced materials designed to withstand extreme temperatures, structural and weight requirements of evolving air and space missions.

Ground-Up Solutions

We consider each system as a whole and integrate with in-house tip-to-tail expertise.

Pushing Hypersonics Forward

Hypersonics require careful thermal management; sophisticated power needs and continuing calls for miniaturization.

Digital Engineering Tools

Digital modeling equals higher-performance weapons that are developed, tested and fielded faster than ever.

Celebrating Over 70 Years of Advanced Propulsion

1950s

- 1951: Northrop Grumman's Maryland facility is reactivated, with approximately 20 employees by 1953, to develop ammonium nitrate jet-assisted take-off (JATO) propellants and motors with the Air Force.

- 1955: Northrop Grumman begins work on Recruit for X-17 flights.

- Falcon becomes Thiokol's (a legacy Northrop Grumman company) first production program; more than 10,000 are produced at Northrop Grumman.

- 1957: Project Farside reaches an altitude of 1,000 miles.

- Cajun begins work on sounding rockets followed by Apache, Iroquois, Tomahawk, Sandhawk, Cherokee, and Yardbird.

- 1958: First Discoverer motors are fired in space and Project Mercury begins.

Photo credit: NASA

1960s and 1970s

- 1960s: Dr. Antonio Ferri designs the first successful scramjet engine; it is tested at General Applied Science Laboratory (GASL, a legacy Northrop Grumman company) in 1961–1964 timeframe under contract to the Air Force Research Laboratory (AFRL).

- GASL performs first shock tunnel tests of hypersonic combustion and builds earliest-known scramjet test complex on Long Island.

- Northrop Grumman supports the Titan II missile with the Stage 2 retro and reentry vehicle vernier motors (STAR 13–class motor); the Titan retro will stay in production for more than 43 years.

- 1970s: GASL collaborates with NASA Langley Research Center (LaRC) to continue development of scramjet technology with the "parametric engine."

Photo credit: Northrop Grumman

1980s and 1990s

- 1985: As a key participant on the X-30 National AeroSpace Plane (NASP) program, GASL is designated "Government Associate Contractor" for the NASP Technology Maturation program.

- 1993: The first solid propulsion hover test is completed on the Lightweight Exo-atmospheric Projectile (LEAP) program on a kill vehicle.

Photo Illustration credit: NASA

2000s

- 2003–2005: NASA selects GASL as prime contractor for the NASA X-43C follow-on program.

- 2004: The X-43 sets a scramjet speed record at Mach 9.3 using a Northrop Grumman engine.

- GASL demonstrates gun-launched scramjet flight testing at Mach 8.

- GASL develops low-cost scramjet flight test technique and demonstrates it with Mach 6 flight program.

- 2007: First freejet test of Northrop Grumman missile scale scramjet.

Photo credit: NASA

2010s

- 2015: First test of additively manufactured Northrop Grumman scramjet combustor.

- 2017: First 15-minute continuous firing of a flightweight scramjet combustor.

- 2018: First test of platform scale (10X) scramjet engine at greater than Mach 4 conditions.

Photo credit: Northrop Grumman

2020s

- 2021: First flight of the Defense Advanced Research Projects Agency (DARPA) HAWC scramjet. Learn More

- 2021: Groundbreaking for the new Hypersonics Capability Center at Elkton, Maryland, setting the stage for the future. Learn More

- 2022: DARPA's OpFires hypersonic missile program successfully demonstrated a new mobile ground-launch system using common military logistics vehicles with a Northrop Grumman rocket motor. Learn More

- 2022: Second flight of the DARPA Hypersonic Air-breathing Weapon Concept (HAWC) scramjet. Learn More

- 2022: US Air Force Selects Raytheon Missiles & Defense, Northrop Grumman to Deliver First Hypersonic Air-Breathing Missile. Learn More

Image developed by Raytheon Missiles & Defense

Media Contact

Anne Eisele

703-996-6658